EDITING .INI File (e.g. adding

COM ports for DirectSOFT)? . . . See

DirectSOFT FAQ0008 & DirectSOFT

FAQ0204

COMMUNICATION Problems? . . . See DirectSOFT

FAQ0013

INSTALLATION Problems? . . . See DirectSOFT

FAQ0016

PRINTING Problems? . . . See DirectSOFT

FAQ0018

DOCUMENTATION Problems? . . . See

DirectSOFT FAQ0040

DirectSOFT FAQ0001 (see

also DS Data FAQ0002)

06-May-2002

Q: Using both DirectSOFT Programming and DS Data simultaneously,

why does my PC lock-up?

A: You are probably using a common link. Instead, create two

different links.

DirectSOFT FAQ0002

21-May-2002

Q: Can I import rung comments in DirectSOFT?

A: Yes, but only in v4.0. Earlier versions do not support this.

DirectSOFT FAQ0003

21-May-2002

Q: How can I prevent my rung comments from getting corrupted?

A: Upgrade to at least DirectSOFT v3.0c Build 80 (many comment

issues were fixed). DirectSOFT v4.0 supports export comments.

Therefore exporting comments often would provide you with a safety

guard in a text format. Also, DirectSOFT v4.0 provides ability to do

backups of project. Also, it is better to work with the project

directly on the hard drive and not a server.

DirectSOFT FAQ0004

21-May-2002

Q: What causes "Error, invalid path values .DTA"?

A: The .DTA files are for Data View in DirectSOFT. If you copied

your project to a different folder, but you didn't copy the .DTA files

as well, you will get this error.

DirectSOFT FAQ0005 (see

also ECOM FAQ0002)

28-May-2002

Q: What causes "Task code error response" with extended E353

error?

A: Error is from PLC and means "timeout in the background

communications." Error is due to backplane comm problem (ECOM, DCM,

etc.)

DirectSOFT FAQ0006

28-May-2002

Q: What causes "Error filter error reading internal op codes

importing TISoft to DS" error?

A: This is a bug that was fixed with DirectSOFT v3.0c Build71 +

patch.

DirectSOFT FAQ0007

29-May-2002

Q: What files are effected by a save?

A: For details, see file DSP

save and load chart2.PDF. The following is a summary of the file

extensions:

File --> Save Project --> to Disk (Ctrl+S):

In DirectSOFT v5.0 there is an additional file effected:

Write-to-Disk (Ctrl+F12) button:

In DirectSOFT v5.0 there is an additional file effected:

DirectSOFT FAQ0008

07-Jul-2017

Q: What things can be setup using the DS600.INI (DS300.INI /

DS400.INI / DS500.INI) file?

A: The following parameters can be added (or adjusted) in the

DS600.INI (DS300.INI / DS400.INI / DS500.INI) file.

To see how to pull up the .INI file for

editing, refer to DirectSOFT FAQ0204.

| PARAMETER NAME | HEADING IN FILE | SYNTAX | NOTES | EXAMPLE |

| COMxEnable | [devasync.dll] | COMxEnable=y | x = COM port number y = 0 (to disable) 1 (to enable) |

COM5Enable=1 |

| ModemEnable | [devasync.dll] | ModemEnable=x | x = 0 (to disable) 1 (to enable) |

ModemEnable=1 |

| EthernetEnable | [devether.dll] | EthernetEnable=x | x = 0 (to disable) 1 (to enable) |

EthernetEnable=1 |

| Autosense | [Comm Server] | Autosense=x | x = 0 (to disable) 1 (to enable) |

Autosense=0 |

| Dump | [devasync.dll] | Dump=x | x = 0 (to disable) 1 (to enable) |

Dump=1 |

| MessageBoxTime | [COMMON] | MessageBoxTime=x | x = <seconds> |

MessageBoxTime=5 |

| PROGRAM COLORS(1) | [PROGRAM COLORS] | x=y | x = parameter number y = color number |

9=16711680 |

| UDPPortNumEnable(2) | [devether.dll] | UDPPortNumEnable=x | x = 0 (to disable) 1 (to enable) |

UDPPortNumEnable=1 |

| PROJECT PATH | [PATHS] | PROJECT PATH=x | x = <folder path> | PROJECT PATH=c:\MyProjects |

| LadderPalette(3) | [SETUP] | LadderPalette=x | x = 0 (to turn off) 1 (to turn on) |

LadderPalette=1 |

| UseLargeBtns(4) | [SETUP] | UseLargeBtns=x | x = 0 (use small

buttons) 1 (use large buttons) |

UseLargeBtns=1 |

| BACKUP PATH | [PATHS] | BACKUP PATH=x | x = <folder path> | BACKUP PATH=c:\MyBackups |

| RTSxDelay | [devasync.dll] | RTSxDelay=y | x = On (for on-delay) Off (for off-delay) y = <milliseconds> |

RTSOnDelay=5 |

| OnTheWeb | [DSLaunch] | OnTheWeb=x | x = 0 (to disable) x = 1 (to enable) |

OnTheWeb=1 |

| Elements |

[Data Sets] | Elements=x |

x = 0 (USA) x = 1 (Japanese) |

Elements=1 |

| Mnemonics | [Data Sets] | Mnemonics=x | x = 0 (USA) x = 1 (Japanese) |

Mnemonics=1 |

| INFLOOPTIMEOUT(5) | [SETUP] | INFLOOPTIMEOUT=x | x = 1 to 4294967296 | INFLOOPTIMEOUT=65536 |

NOTES:

(1) - Only use this to fix a problem (e.g. DirectSOFT

FAQ0020, DirectSOFT FAQ0043). The

parameter and color numbers are not defined in a user-friendly manner.

(2) - Became available with DirectSOFT v3.0c Build 54

(01-Sep-2000)

(3) - Became available with DirectSOFT v4.0 Build 18

(09-Dec-2002)

(4) - Only available in DirectSOFT v4.0. Not available in

DirectSOFT v5.0.

(5) - Only modify this if you have received the "Infinite Loop

Timeout" message. This parameter became available with DirectSOFT v4.0

Build 20 (27-Jun-2003).

DirectSOFT FAQ0009

07-Jun-2002

Q: Getting CSMain.exe error when doing a Find for an element in

Ladder view.

A: Upgrade to at least v3.0c Build71 +patch or v4.0.

DirectSOFT FAQ0010

19-Mar-2010 (see also LookoutDirect FAQ0016)

Q: In DirectSOFT under Add Link get double listings (two COM1's,

two COM2's, two Ethernets, two DL250s, etc.).

A: One of 4 things has probably happened:

The bottom line is that you have multiple copies of the Devasync.DLL and Devether.DLL files and you only need one. To fix search your hard drive and delete all copies of these two files except the ones in the DirectSOFT installation folder, BIN folder (e.g. c:\DirectSOFT5\Bin).

DirectSOFT FAQ0011 (see

also DS Data FAQ0053)

13-Jun-2011

Q: Trying to get USB adapter to work, getting "Comm Error - Cannot

access comm port. The port may not be present or another application

might be using it."

A: Make sure that there are not any other devices (like internal

modems) using the COM port that the USB adapter driver is trying to

use. Also, it is recommended that you upgrade DirectSOFT to at least

v4.0 Build 18, or v3.0 Build 80. Or make sure you use a USB that has

been approved and tested by Host Engineering for use with DirectSOFT.

Also, it is recommended that you:

This list is updated as we go:

DirectSOFT FAQ0012

17-Jun-2002

Q: Using Targus USB converter, WinXP, Toshiba Satellite 2405 S201,

getting, "Error connecting to PLC"

A: Host has not tested the Targus USB converter and it is

therefore we cannot recommend it. However, upgrading your DirectSOFT

to the latest Build is always recommended because Host continuously

attempts to improve communications with the wide variety of USB

drivers now being sold. (see DirectSOFT FAQ0011

for list of compatible USBs).

DirectSOFT FAQ0013 (see

also DS Data FAQ0045; similar to ECOM FAQ0024; similar to EZ Ethernet

FAQ0005)

10-Mar-2014

Q: Need general help on communications from PC to PLC and

establishing a link.

A: First of all, always make sure you are using the latest version

of DirectSOFT possible.

Secondly, if you are using an ECOM and

have WinXP on your PC with a firewall (particularly with SP2), then you

must do one of the following:

(1) Turn the firewall off, or

(2) Create an exception for CSMAIN.EXE

application (located in the BIN folder under your DirectSOFT folder), or

(3) Create an exception for port #0x7070

(28784) for both TCP and UDP protocols, which is the port number that

all of our Ethernet devices use for communication.

Thirdly, you can control which

communications resources on your PC you want to let DirectSOFT use by

entries in the DirectSOFT initialization file (DS500.INI):

COMMUNICATIONS RESOURCES

You must edit DirectSOFT's DS500.INI file to change communication

resources.

(To pull up the .INI file for editing, see DirectSOFT

FAQ0204)

There are 3 parameters that can be

modified regarding communication resources:

(1) COMxEnable - To edit this resource in the

.INI file, see DirectSOFT FAQ0008.

(2) ModemEnable - To edit this resource in the

.INI file, see DirectSOFT FAQ0008.

(3) EthernetEnable - To edit this resource in

the .INI file, see DirectSOFT FAQ0008.

NOTE: In some extremely rare cases with DirectSOFT versions older than v4.0, to totally disable Ethernet resources you not only have to do the above, but also you may need to rename the files Devether.DLL and Protoecm.DLL to Devether.OLD and Protoecm.OLD. Don't forget to rename them back after troubleshooting!

STARTUP

MODEM LINKS

Modem links must be configured manually. Here is a checklist for getting a modem connection working:

USB-TO-SERIAL

These devices have drivers with them that

should make them act like regular COM ports. (See DirectSOFT

FAQ0011 for approved USB-to-Serial devices tested by Host

Engineering). However there have been a few vendors that don't do this

with their drivers. DirectSOFT "thinks" it is talking to a COM port,

Ethernet NIC, or modem. It doesn't know a USB-to-serial device.

The order of installation, however, seems to be important:

AUTOSENSE

Once links have been created for

DirectSOFT, it validates these each time you start it. You can stop

this from happening by editing the .INI file and changing AutoSense:

- To pull up the .INI file for editing, see DirectSOFT

FAQ0204.

- To edit Autosense parameter in the .INI file, see

DirectSOFT FAQ0008.

DUMP (for troubleshooting

SERIAL and MODEM links)

When you can't figure why things won't

work exactly right, you can use this debug function with a little help

from Automation Direct, or Host Engineering. This parameter is in the

.INI file.

- To pull up the .INI file for editing, see DirectSOFT

FAQ0204.

- To edit Dump parameter in the .INI file, see DirectSOFT

FAQ0008.

After making this change you should start the debug window logger:

DirectSOFT FAQ0014

24-Jun-2002

Q: Mouse scroll wheel doesn't work in DirectSOFT, but works in

other applications.

A: The first thing to try is to update to at least DirectSOFT

v4.0 Build 24. If that doesn't work then you may need to download the

mouse control software for your mouse. For example, download and

install Microsoft Intellipoint for Microsoft mice, and Logitech

MouseMan software for Logitech mice, etc.

DirectSOFT FAQ0015

25-Jun-2002

Q: Using DirectSOFT v3.0c Build 71 + patch; why is there no option

to export program to CSV file.

A: This is not supported in v3.0c, must have v4.0.

DirectSOFT FAQ0016

10-Jun-2010

Q: Having DirectSOFT installation problems.

A: Primary things to check before consulting the errors listed

below:

Below are various installation errors that have been encountered and their solutions.

DirectSOFT FAQ0017

22-Oct-2007

Q: Why are there instructions listed in the DirectSOFT Help file

that do not show any support for the DL CPUs? (e.g. COS, ACOS,

ATAN).

A: Because Koyo (the maker of the DL PLCs) sells a larger PLC with

a superset of the instructions listed for the AutomationDirect PLCs

and DirectSOFT supports those CPUs as well. But these PLCs are sold to

a very specific market in Japan and are not available otherwise.

DirectSOFT FAQ0018

29-Jan-2010

Q: Trying to print from DirectSOFT and having various problems.

A: Various printing issues are listed below:

DirectSOFT FAQ0019

28-May-2002

Q: Importing CSV file causes DirectSOFT to crash.

A: We work very hard to keep all reported crashes from happening.

If a crash happens with an import, the first thing to do is to upgrade

to the latest Build for your version. So far this has fixed every case

to date.

DirectSOFT FAQ0020

28-May-2002

Q: Pressing the Default button for color options (View, Color

Setup) does not restore the colors to their defaults.

A: This is a bug in v3.0c Build71 (or less), v4.0 Build16 (or

less). To fix, upgrade to later versions. Temporary workaround is to:

DirectSOFT FAQ0021

03-Jun-2002

Q: Help file is hard to use.

A: Host is continuing to update and improve the help file, but

the manual is always up-to-date.

DirectSOFT FAQ0022

15-Nov-2002

Q: Having trouble connecting to Port 1 of DL250. Port 2 works

fine.

A: Port 1 is K-seq protocol only. Next, make sure the link

properties are 9600 bps, 8 data bits, odd parity. Also don't rule out

the possibility that the port on the DL250 could be bad, or that the

cable is bad.

DirectSOFT FAQ0023

12-Nov-2007

Q: Why are stages shown out of numerical sequence in Stage View?

A: The order is determined by a very complex algorithm and cannot

be changed. However, we are considering options for future DirectSOFT

releases.

DirectSOFT FAQ0024

09-Dec-2002

Q: Need to scroll through the program that advances the screen to

the next stage. Currently have to scroll down until it is found.

A: Should use Stage View. This allows one to navigate through

Stages easily.

DirectSOFT FAQ0025

02-Jan-2019

Q: How can I copy the links from one DirectSOFT installation to

another (e.g. on a different PC)?

A: The links in DirectSOFT are stored in the CommServ.RST file

located in the Bin folder located under DirectSOFT installation

folder. All you have to do is copy this file from one Bin folder to

the other. However with the advent of DirectSOFT v6.2, the destination

Bin folder is different.

|

DirectSOFT VERSION |

Source of CommServ.RST | Destination of CommServ.RST |

| v4 | c:\DirectSOFT4\Bin | c:\DirectSOFT4\Bin |

| v5 | c:\DirectSOFT5\Bin | c:\DirectSOFT5\Bin |

| v6.0 | c:\DirectSOFT6\Bin | c:\DirectSOFT6\Bin |

| v6.1 | c:\DirectSOFT6\Bin | c:\DirectSOFT6\Bin |

| v6.2 | c:\Users\Public\Documents\DirectSOFT6\Bin | c:\Users\Public\Documents\DirectSOFT6\Bin |

| v6.3 | c:\Users\Public\Documents\DirectSOFT6\Bin | c:\Users\Public\Documents\DirectSOFT6\Bin |

DirectSOFT FAQ0026

15-Jan-2003

Q: What is the earliest version of DirectSOFT that supports

Exporting Documentation?

A: DirectSOFT Programming v3.0.

DirectSOFT FAQ0027

16-Jan-2003

Q: When you enable the Dump function in the DS500.INI file, where

does it place the dump file?

A: After editing this parameter in the DS500.INI file you must

start the Dbwin32.EXE program. Then in that window you can save the

dump to any filename you like.

- To pull up the .INI file for editing, see DirectSOFT

FAQ0204.

- To edit the Dump parameter in the .INI file, see DirectSOFT

FAQ0008.

DirectSOFT FAQ0028

17-Jan-2003

Q: Can DirectSOFT program an SA-21 (0.5K-words version of

D3-330P)?

A: Yes.

DirectSOFT FAQ0029

17-Jan-2003

Q: Saving or opening a project gets an error. "Couldn't open new

database. Reopened failed." But can still get program to come up.

A: Check the Projects Path in the DS500.INI file and make sure it

is pointing to a folder that you have access to.

- To pull up the .INI file for editing, see DirectSOFT

FAQ0204.

- To edit the PROJECT PATH parameter in the .INI file, see

DirectSOFT FAQ0008.

DirectSOFT FAQ0030

21-Jan-2003

Q: What is the meaning of all the files in a project?

A: See DSP save

and load chart2.pdf document.

Summary:

CSV - Comma separated variable

CWB - Counter I/O configuration

DTA - Data view

DV - DV1000 setup

ERM - Ethernet remote master config

ESD - Element documentation (nickname, wiring info, description)

ESX - Index for element documentation

INF - Project information

LCD - Ladder comment data

LCX - Ladder comment index

LDA - Maps rung comments to rung #'s

LDO - Online only, maps rung comments to rung #'s (temporarily until

saved offline to LDA file)

PID - PID documentation

PRJ - Ladder program

PRT - Print layout config

RD - 305 R-memory data

RF - 305 R-memory data editor format

SCD - Stage comments

SCX - Index for stage comments

TLS - PLC parameters, I/O configuration, pause bits

TXT - Text file

VD - V-memory data

VF - V-memory editor format

WSP - DirectSOFT window layout

In DirectSOFT v5.0 there is an additional file in the project:

XML - Docking-pane screen coordinates

DirectSOFT FAQ0031

21-Jan-2003

Q: Is the 330S in DirectSOFT the same as a 330P?

A: Yes.

DirectSOFT FAQ0032

21-Jan-2003

Q: Can source code of DirectSOFT be obtained?

A: The source code of DirectSOFT is not for sale.

DirectSOFT FAQ0033

21-Jan-2003

Q: Does Host customize DirectSOFT for customers?

A: Customizing DirectSOFT is not something Host has the resources

to devote to at this time (January 2003).

DirectSOFT FAQ0034

24-Jan-2003

Q: Why do the messages in DirectSOFT come up in German?

A: You have Siemens Step7 software installed on your PC. First

try renaming the MFC42LOC.DLL file to *.OLD and reboot. If that

doesn't work you may have to uninstall both Step7 and DirectSOFT and

then just reinstall DirectSOFT.

DirectSOFT FAQ0035

10-Sept-2002

Q: Are there any plans to have Ladders view wrap around instead of

scrolling?

A: Host Engineering does not have any plans to change the

scrolling Ladders to a wrap-around view.

DirectSOFT FAQ0036

02-Jan-2019

Q: What version of firmware in the DL-PLC is required for

DirectSOFT v5.x IBoxes to function?

A: IBoxes are supported only in DL05, DL06, DL250-1, DL260 &

DL450 CPUs:

| Direct Logic CPUs | CPU Firmware |

| 05 | v5.10 or later |

| 06 | v2.10 or later |

| 130 | |

| 230 | |

| 240 | |

| 250 | |

| 250-1 | v4.60 or later |

| 260 | v2.40 or later |

| 262 | ALL |

| TI-325 | |

| 330 | |

| 330P | |

| TI-330S | |

| TI-335 | |

| 340 | |

| 350 | |

| TI-425 | |

| 430 | |

| TI-435 | |

| 440 | |

| 450 | v3.30 or later |

| 454 | ALL |

DirectSOFT FAQ0037

(similar to DirectSOFT FAQ0013; see also DS Data FAQ0046)

03-Feb-2003

Q: First time starting DirectSOFT v4.0, crashes and gets

CSMain.exe error.

A: The first thing to check is to make sure that IPX protocol is

loaded for the NIC that is installed (see DirectSOFT

FAQ0183 for installing protocols). Part of this problem was

remedied in v4.0 Build 18 so upgrading may very well fix the problem.

ReadMe_P.htm file says: "3. CommServer -- Fixed CommServer crash

when IPX not installed -- we hope!" However, we know there are

still some other issues centered around IPX protocol that we are

currently debugging.

DirectSOFT FAQ0038

16-Jul-2002

Q: Does DirectSOFT support USB converters that work, not as COM

devices, but rather show up as an Ethernet device?

A: No. The type of USBs that DirectSOFT supports are those that

show up as COM devices. Ethernet-to-USB will not work because in order

to talk to Ethernet, DirectSOFT assumes that you have an ECOM. Thus if

you make an Ethernet link, DirectSOFT wants to talk to an ECOM not a

serial device. Thus when the Ethernet-to-USB converter converts the

Ethernet signals to USB, then the serial device will not understand

the ECOM protocol. See DirectSOFT FAQ0011 for

compatible USBs.

DirectSOFT FAQ0039

04-Feb-2002

Q: Will DirectSOFT export a Ladder file to Tisoft .VPU format?

A: No.

DirectSOFT FAQ0040

21-Apr-2023

Q: Having various problems with documentation files (comments,

etc.); can this be fixed?

A: There are known problems that can occur when documentation

files get corrupted. When corruption has occurred it can cause quite a

variety of unpredictable symptoms. Some of the more common:

The most common corruption is with

the Element Documentation files since these are edited the most

frequently. Element documentation is contained in two files:

The other databases have similar files:

Sometimes when any of these are corrupted they will be unusually large, or larger than they are normally.

There are three main ways to

possibly recover documentation.

(1) AUTOSAVE

RESTORATION

The easiest way to recover from any corruption of the documentation files is to revert back to an earlier version of these files before the corruption occurred. DirectSOFT6 has an AutoSave feature by default, and every time you save your project, it makes a date-time-stamped backup copy and keeps four of these. These are located in the following folder:

c:\User\Public\Documents\DirectSOFT6\Projects\Backup\AutoSave\<YourProjectName>\<DateTimeStamp>\

You can browse there and copy, for example, the ECX and ESD files over to your corrupted project files replacing them with these backups.

(2) EXPORT/IMPORT DOCUMENTATION

Sometimes this works. If your

Element Documentation is corrupt, you can choose File -->

Export --> Element Documentation, and make a TXT file of the

documentation. Then delete (or rename them if you want to save them in

case this doesn't work) the current ECX and ESD files. Then attempt to

do a File --> Import --> Element Documentation, of the

TXT file you just created.

(3) MANUALLY

COPY/PASTE DOCUMENTATION

If all of your backups are corrupted, you will have to use a bit more tedious method. This involves the following steps (for Element Documentation corruption).

If this doesn't work, you may have

to contact technical support (support@hosteng.com).

A similar procedure can be done for

the Ladder comments and Stage comments paying attention to the file

extensions mentioned above.

DirectSOFT FAQ0041 (see

also ECOM FAQ0010)

04-Feb-2003

Q: Is it possible to run 2 NICs on 1 PC to 2 separate ECOMs?

A: Yes. But the only way Host has seen this work is if one NIC

has IPX-only protocol loaded (and not TCP/IP), and the other NIC has

TCP/IP-only protocol loaded (and not IPX). DirectSOFT has no other way

to choose between which NIC to use. see DirectSOFT

FAQ0183 for installing protocols.

DirectSOFT FAQ0042

07-Jul-2002

Q: Used the "Save As..." function and lost documentation!

A: This was a known bug. If you used "Save As..." and then used

the same filename for the project documentation would inadvertently

get deleted! This was fixed in DirectSOFT v3.0 Build 62. However, the

newer Build 71 and Build 71 patch reintroduced the bug because the

code (contained in prgrm30.dll) that gets replaced is actually old

Build 59 code (3.0.059). Problem completely eradicated in v3.0c Build

80 and any version of v4.0.

DirectSOFT FAQ0043

19-Jun-2002

Q: Is there a color setup for monochrome monitors?

A: Monochrome color selection button (View --> Color

options...) has been added to v4.0 Build 18. For earlier versions

you:

DirectSOFT FAQ0044

04-Feb-2003

Q: Using DirectSOFT v2.0 Build 23, trying to communicate to DL250,

get "Unknown PLC type" and then "Attempted access of unlocked

device."

A: Support was added for the DL250 to DirectSOFT v2.1. Since this

is no longer available, you should upgrade all the way to at least

v2.4a. It's free and can be downloaded from Host website. See DirectSOFT

FAQ0059 for a table showing which versions of DirectSOFT support

which DL CPU.

DirectSOFT FAQ0045

20-Dec-2007

Q: In the DL06, when Aliases are turned ON, why does the RX/WX

instruction show V1200 as CTA200, but the LD instruction doesn't?

A: This has to do with the fundamental function of the addressing

parameter of RX/WX instruction versus the LD instruction. The RX/WX

parameter is the remote PLC's address, whereas

the parameter of the LD instruction is the local

PLC's address. Thus, with Aliases turned ON we chose to use the

Aliases of the "biggest" DL-PLC that Automation Direct sells (DL450)

for the naming of the RX/WX parameter. Examples:

In DL06 with Alias turned OFF:

LD V1200 ; No Alias names are displayed for any instruction.

RX V1200 ; No Alias names are displayed for any instruction.In DL06 with Alias turned ON:

LD V1200 ; Not displayed as CTA200 because in DL06 counters only go to CTA177.

RX CTA200 ; The Alias for DL450's V1200 is used. DL450's counters go up to CTA377.

If, however, you use a smaller V-memory location in the DL06 we get:

In DL06 with Alias turned OFF:

LD V1177 ; No Alias names are displayed for any instruction.

RX V1177 ; No Alias names are displayed for any instruction.In DL06 with Alias turned ON:

LD CTA177 ; V1177 = CTA177 in DL06.

RX CTA177 ; V1177 = CTA177 in DL450 as well.

To turn Aliasing ON or OFF:

(1) From DirectSOFT menu: View

--> Options...

(2) Select the Global tab.

(3) Check or Uncheck "Display Aliases".

(4) Press <OK>.

DirectSOFT FAQ0046

04-Feb-2003

Q: Can you create an Ethernet link offline?

A: Yes.

For DS Launch:

If inside DirectSOFT:

DirectSOFT FAQ0047

04-Jan-2008

Q: When configuring a serial link using DirectSOFT, what does the

"Radio Link" selection on the Port tab do?

A: This was added in DirectSOFT v4 Build 23 (25-May-2004) so that

DirectSOFT could assert the DTR line for the CR-HN series radio modems

Automation Direct sells.

DirectSOFT FAQ0048 (see

also ECOM FAQ0042; DL Plus FAQ0009; DNLoader FAQ0010; DSData FAQ0005;

EZ Ethernet FAQ0008; HA-TADP FAQ0002; Lookout Direct FAQ0014; NetEdit

FAQ0005; SDK FAQ0020)

31-Jan-2008

Q: Why doesn't the ECOM use subnet mask or gateway address like the

ECOM100?

A: Since the ECOM doesn't do "master"-type communications, it

doesn't use the subnet mask or gateway address. Whatever talks to the

ECOM will be using IPX or UDP/IP, and the ECOM simply swaps the

destination and source addresses in the telegram and responds in this

way, not "caring" about the subnet or gateway. However, the ECOM100

acts more like a conventional TCP/IP device. The ECOM100 has the

capability to be a master and has a full-blown TCP stack inside. Thus,

if it is to transmit to an IP address not on its subnet, it will, of

course, transmit to its configured gateway address instead.

DirectSOFT FAQ0049

09-Feb-2003

Q: How do I upgrade to the latest version of DirectSOFT?

A: If you have DirectSOFT v4.0, or earlier versions, then you

will have to order the upgrade from Automation Direct:

Automation Direct

3505 Hutchinson Road

Cumming, GA 30040

800-633-0405

http://www.automationdirect.com

If you already have DirectSOFT v5, then you can download maintenance upgrades by:

DirectSOFT FAQ0050

19-Nov-2002

Q: Can I copy contacts from one rung to another?

A: This feature is not in the current versions of DirectSOFT

(v3.0 Build 80; v4.0 Build 18) and there are no plans to add this to

these versions. However, this feature will be included in v5.0 of

DirectSOFT (no date as to release). Also, to get around this issue

now, it is possible to Export the Program to a text file, then use the

copy and paste of your favorite text editor to copy contacts from rung

to rung. Then use the Import Program to get them back into DirectSOFT

project.

DirectSOFT FAQ0051

28-Aug-2002

Q: It would be nice to have the optional lines already added to

the DS400.INI (or DS300.INI, DS500.INI) file, yet commented out, so

one doesn't have to try to remember what to type in, or what heading

to put them under, especially since these are not always documented.

A: Added the following to DS400.INI (& DS500.INI) file in

DirectSOFT v4.0 Build 18 (to activate them, you simply remove the

";"):

[Comm Server]

;AutoSense=0 (To turn OFF autosensing of Comm Links during Comm Server

startup.)

[devasync.dll]

;Dump=1 (To enable a dump of Serial Port debugging information.)

[devether.dll]

;UDPPortNumEnable=1 (To enable display of the UDP Port Number.)

- To pull up the .INI file for editing, see DirectSOFT

FAQ0204.

- To edit the above parameters in the .INI file, see

DirectSOFT FAQ0008.

DirectSOFT FAQ0052

10-Dec-2002

Q: Can I open the same project with two instances of DirectSOFT on

two different PCs?

A: No. If you do, then unpredictable results can happen. (e.g.

comment files can be corrupted!). DirectSOFT doesn't comprehend other

instances of itself wanting to use the same project file. It is only

one client per project at a time. However, we are considering putting

a mult-client feature in v5.0.

DirectSOFT FAQ0053

12-Feb-2003

Q: Does DirectSOFT have problems opening up projects that are

read-only?

A: Yes. DirectSOFT needs to open up the files as read/write.

DirectSOFT FAQ0054

13-Dec-2002

Q: There is no information in the v4.0 Build 16 help file

regarding the setup of the second comm port of the DL06 or the

DL260.

A: This was added to Build 18. Read_Me.htm file says, "29. Setup

Secondary Comm Port Dialogs now show correct Help files based on PLC

type."

DirectSOFT FAQ0055

12-Feb-2003

Q: How can I change the default project folder that DirectSOFT

uses?

A: You must edit the PATH parameter in DirectSOFT's DS500.INI

file. After changing this parameter, then when you use "Save" or "Save

As..." or "Open," etc., this will be the default folder.

- To pull up the .INI file for editing,

see DirectSOFT FAQ0204.

- To edit the PATH parameter in the .INI file, see DirectSOFT

FAQ0008.

DirectSOFT FAQ0056

18-Feb-2003

Q: If customer has an OEM-created DirectSOFT v2.0, can he update

to v2.4 from website?

A: Yes.

DirectSOFT FAQ0057

18-Feb-2003

Q: When trying to download and make diskettes for DirectSOFT v2.4a

from website, get "Not enough space on disk."

A: You must first download the file on the website to your hard

drive, then execute it (double-click), then choose "Make disks" from

menu.

DirectSOFT FAQ0058

19-Feb-2003

Q: What is the difference between the Demo version of DirectSOFT

and the regular version?

A: Depending on which version of DirectSOFT demo you are talking

about:

The DirectSOFT v3.x and v4.x DEMO version:

The DirectSOFT5 DEMO version (called DS100):

DirectSOFT FAQ0059

02-Jan-2019

Q: Trying to load a project but getting "DirectSOFT recognizes the

document <filename> but features or support level is not

installed."

A: This error usually means one of the following 3 things:

| Direct Logic CPUs | DirectSOFT Version | |||||||||||||||||

| v1.12i | v2.0 | v2.1 | v2.2 | v2.3 | v2.3a | v2.4 | v2.4a | v3.0 | v4.0 | v5.0 | v5.1 | v5.2 | v5.3 | v6.0 | v6.1 | v6.2 | v6.3 | |

| 05 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | ||||||

| 06 | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||||||||

| 130 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |

| 230 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 240 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 250 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | ||

| 250-1 | (1) | (1) | (1) | (1) | (1) | (1) | (1) | Y | Y | Y | Y | Y | Y | Y | Y | Y | ||

| 260 | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||||||||

| 262 | Y | |||||||||||||||||

| TI-325 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 330 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 330P | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| TI-330S | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| TI-335 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 340 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 350 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |||

| TI-425 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 430 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| TI-435 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 440 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| 450 | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | |

| 454 | Y | Y | Y | |||||||||||||||

(1) Partially compatible. The restriction is that the 250-1 local expansion I/O cannot be seen in DirectSOFT.

DirectSOFT FAQ0060

04-Mar-2003

Q: Can I use the RTS/CTS Flow Control setting in the Link Wizard

to talk from DirectSOFT to DL PLC?

A: No. The reason is that the PLC port does not listen to its CTS

line for incoming data. It only uses the Flow Control RTS/CTS lines

when it wants to send data. So, if you choose RTS/CTS Flow Control in

DirectSOFT, then when DirectSOFT wants to talk to the PLC, it will set

the RTS line, which, if wired correctly, would tell the PLC it wants

to send data. However, because the PLC is not listening to that line,

it would never send DirectSOFT the CTS, so DirectSOFT would time out.

This begs the question, "Why is the Flow Control option selectable in DirectSOFT?" The answer is that if you used a Serial Link to say, COM1, and had an external modem, for example, the modem would be listening to the RTS line and would respond properly. But the PLC port does not function in this manner.

This also begs the question, "Why is Flow Control configurable on the PLC Port?" The answer is that it was specifically designed for sending data to the F2-UNICON and FA-ISONET devices.

DirectSOFT FAQ0061

28-Feb-2003

Q: While a Ladders program is pulled up, can I switch to a

different CPU?

A: Yes. Use PLC --> Disconnect; move the communication cable

(if necessary); then use PLC --> Connect. However, keep in mind

that a program has a CPU type associated with it. This is very

necessary for programming due to the different ranges of the PLCs as

well as their different functions. (You can display what CPU type is

associated with the program by using File --> Properties). For

example, there are many more functions available for a DL06 than there

are for a DL240.

DirectSOFT FAQ0062

06-Mar-2003

Q: After making a link to TI335 using an Automation Direct DCU, it

is seen as a "stage CPU" and repeatedly gets "Knowledge base

mismatch - cannot connect" error.

A: This is a known problem with a TI335. Here are some things to

try:

DirectSOFT FAQ0063 (see

also ECOM FAQ0013)

27-Sep-2010

Q: Connecting to DL PLC with ECOM and getting "????" as the CPU

type; or just getting communications errors.

A: Check the following:

DirectSOFT FAQ0064

04-Feb-2008

Q: How can I disable/enable the "DirectSOFT on the Web" feature in

DSLaunch?

A: By default, the "DirectSOFT on the Web" feature is

enabled in DSLaunch.

DirectSOFT FAQ0065

(similar to DS Data FAQ0009; see also DS Data FAQ0034; ECOM FAQ0014)

07-Mar-2003

Q: How can I speed up the data throughput of my ECOM?

A: Consider the following:

DirectSOFT FAQ0066 (see also ECOM FAQ0016; DS

Data FAQ0089; similar to Do-more FAQ0035)

05-Nov-2019

Q: How can I make a link with DirectSOFT (or DS Data) to a single

ECOM/ECOM100 or multiple ECOMs/ECOM100s over the Internet?

A: There are a number of ways to accomplish this due to the

versatile ways in which Internet connectivity is established.

Method #1 (Direct Connect): Requires the remote ECOM/ECOM100(s) to have a registered Internet IP address.

Method #2 (Indirect Connect): Requires access to the remote gateway/router which must be configured to translate TCP port #s.

Method #3 (ISP VPN): Requires the ISP (Internet Service Provider) set up a VPN (Virtual Private Network).

Method #4 (VPN Software): Requires the use of some form of VPN software (e.g. PC Anywhere, LogMeIn, etc.).

Multiple ECOM/ECOM100 Instructions: In this method if connecting to multiple ECOM/ECOM100s, it is assumed that each ECOM/ECOM100 has its own registered Internet IP address and therefore to connect to each of them only requires that you make separate links to each one.

DirectSOFT Link Configuration to connect to PLC1:

1. Build link in DirectSOFT.

a. On PLC tab select:

PLC Family - Direct LOGIC 205 Series

PLC Type - 250

b. On the Port tab select:

Devices - Ethernet

Transport - Winsock

Transport Protocol - UDP/IP

Node Address - IP Address xxx.xxx.xxx.xxx (Registered Internet IP Address of your ECOM)

Advanced Settings - Timeout (Increase?)

NOTE: To determine how much the "Timeout" setting should be increased:

1. Go to the DOS Command Prompt (Start --> Programs --> Accessories --> Command Prompt)

2. Type in: ping xxx.xxx.xxx.xxx (Registered Internet IP Address of your ECOM)

3. Make note of the "Maximum" time as listed and increase this number by at least 50%.

4. Enter this number as the "Timeout" setting.

UDP Port Number (if it is displayed) - 28,784 (this is the default; must always be this number)

c. On the Protocol tab select:

Protocols - ECOM

d. Click <Auto>. Should beep for success.

e. Enter a name for the link and click <Accept>.

Multiple ECOM/ECOM100 Instructions: In this method if connecting to multiple ECOM/ECOM100s, they are assumed to be located behind the gateway/router on an internal network with internal IP addresses assigned to them. Therefore, the DirectSOFT (or DS Data) links to each of them must use the same IP address of the gateway/router (because from the Internet, that is all it can see). Thus, the only way to differentiate between the multiple ECOM/ECOM100s on the other side of the gateway is by DirectSOFT (or DS Data) using different TCP port #s for each. In order to accomplish this 2 things must be done: (1) DirectSOFT (or DS Data) must have this feature turned ON by editing the .INI file, and (2) the remote gateway/router must be configured to translate the TCP port #s to different IP addresses behind its firewall.

DirectSOFT Link Configuration to connect to PLC4:

1. Edit .INI file and set UDPPortNumEnable=1

- To pull up the .INI file for editing, see DirectSOFT FAQ0204.

- To edit the UDPPortNumEnable parameter in the .INI file, see DirectSOFT FAQ0008.

2. Build link in DirectSOFT.

a. On PLC tab select:

PLC Family - Direct LOGIC 205 Series

PLC Type - 250

b. On the Port tab select:

Devices - Ethernet

Transport - Winsock

Transport Protocol - UDP/IP

Node Address - IP Address xxx.xxx.xxx.xxx (Registered Internet IP Address of your Gateway/Router)

Advanced Settings - Timeout (Increase?)

NOTE: To determine how much the "Timeout" setting should be increased:

1. Go to the DOS Command Prompt (Start --> Programs --> Accessories --> Command Prompt)

2. Type in: ping xxx.xxx.xxx.xxx (Registered Internet IP Address of your Gateway/Router)

3. Make note of the "Maximum" time as listed and increase this number by at least 50%.

4. Enter this number as the "Timeout" setting.

UDP Port Number - 28,787 (can be any free configurable Port # on your particular Gateway/Router)

c. On the Protocol tab select:

Protocols - ECOM

d. Click <Auto>. Should beep for success.

e. Enter a name for the link and click <Accept>.Gateway Configuration Table:

PLC DirectSOFT Link Node Address (Gateway) DirectSOFT Link Port # Nontranslated ECOM Node Address ECOM Port # (cannot be changed) PLC1 xxx.xxx.xxx.xxx

(your Gateway/Router IP)

28,784 (0x7070) 192.168.20.1 28,784 (0x7070) PLC2 xxx.xxx.xxx.xxx

(your Gateway/Router IP)28,785 (0x7071) 192.168.20.2 28,784 (0x7070) PLC3 xxx.xxx.xxx.xxx

(your Gateway/Router IP)28,786 (0x7072) 192.168.20.3 28,784 (0x7070) PLC4 xxx.xxx.xxx.xxx

(your Gateway/Router IP)28,787 (0x7073) 192.168.20.4 28,784 (0x7070)

This method requires that you work with your ISP (Internet Service Provider) and have them set up a VPN (Virtual Private Network) for you so you can connect to the remote network where the ECOM/ECOM100s are located. There are quite a variety of ways in which your ISP can do this for you. Some may require you use their own software to do it. But in most cases once the VPN is established, the connection to the ECOM/ECOM100s on the remote network is exactly like Method #1 (Direct Connect) above.

Multiple ECOM/ECOM100 Instructions: Once VPN connection is established it is assumed that each ECOM/ECOM100 has its own IP address on the remote network and therefore to connect to each of them only requires that you make separate links to each one.

This method requires the use of some form of VPN software (e.g. PC Anywhere, LogMeIn, etc.). The ECOM/ECOM100 cannot be accessed directly with this method but instead the VPN software allows you to control a PC (with DirectSOFT (or DS Data) installed) at the remote site that is on the same network as the ECOM/ECOM100s. Thus, after the connection using the VPN software is established, the connection to the ECOM/ECOM100s on the remote network is exactly like Method #1 (Direct Connect) above.

Multiple ECOM/ECOM100 Instructions: Once VPN connection is established it is assumed that each ECOM/ECOM100 has its own IP address on the remote network and therefore to connect to each of them only requires that you make separate links to each one.

DirectSOFT FAQ0067 (see

also ECOM100 FAQ0059)

22-Sep-2009

Q: When using the IBox ECEMAIL (IB-711), getting various error

codes:

A: These error codes are defined in the description of SMTP

protocol called RFC 821. Here are some of the specific codes we have

seen and their solutions. Otherwise, you can download RFC

821 here, or download this

PDF with some sample solutions, or look up the error codes on

the Internet to find other solutions:

DirectSOFT FAQ0068

04-Jun-2002

Q: There is nothing in the manual nor the help file that indicates

the maximum size of the documentation fields.

A: DirectSOFT v4.0 software has this added to the help file:

Here you will see that the size of the documentation fields are listed as:

Automation Direct is currently adding this information to the manual.

DirectSOFT FAQ0069

07-Jun-2002

Q: Import Documentation rejects using a Nickname of "S0".

A: That is true. S0 is a valid Element Name and means "Stage Bit

0." Therefore it is not possible to assign a valid Element Name as a

Nickname.

DirectSOFT FAQ0070

07-Jun-2002

Q: Import Documentation imports Nickname "UB" as "-----".

A: That is true. "UB" is a valide Nickname and means "Unassigned

Bit." This is a type of unassigned Nicknames that DirectSOFT will

allow you to create. This means that you can have Nicknames that do

not have corresponding Elements assigned to them. Normally in the

Documentation Editor, these show up as "-----" under the Element Type.

When these are Exported, however, instead of getting the "-----" in

the text file, you will see things like "UB" or "UW."

These have certain meanings based on the following list. If generating documentation outside of DirectSOFT (like in an Excel CSV file), use these types based on the following list. They will show up in your Documentation Editor with "-----" under the Element Type:

In summary, DirectSOFT exemplifies the following behavior:

DirectSOFT FAQ0071

12-Jun-2002

Q: The PID View window doesn't show Autotune.

A: This is a known display bug with DirectSOFT v4.0 in Builds

less than Build 20. You can either download the latest Build or simply

resize the PID View window and Autotune will appear.

DirectSOFT FAQ0072

25-Jun-2002

Q: I have two copies of the DS400.INI file, one in the Windows

directory and one under the DirectSOFT4 folder. Which one do I

modify if I want to change the startup characteristics of

DirectSOFT?

A: The one in your Windows directory is the one utilized by

DirectSOFT. This extra copy of the DS400.INI file has been removed

from later versions of DirectSOFT. However, the easiest thing to do to

make sure you are modifying the correct one is to edit the .INI file

from the Windows Start menu (see DirectSOFT

FAQ0204).

DirectSOFT FAQ0073 (see

also DS Data FAQ0092)

10-Nov-2008

Q: How can I change the number of COM ports that DirectSOFT / DS

Data makes available for me to use?

A: By default older versions of DirectSOFT and DS Data had COM1,

COM2, COM3 and COM4 ports available by default. However, due to the

fact that most PCs these days only have COM1 and COM2, DirectSOFT and

DS Data have been changed so that COM3 and COM4 are now disabled by

default. This change was made for DirectSOFT and DS Data v4.0 Build

18. However, it is possible to enable and disable PC COM ports up to

COM199. In order to change your COM port configuration you must edit

DirectSOFT's DS500.INI file:

- To pull up the .INI file for editing,

see DirectSOFT FAQ0204.

- To edit the COMxEnable parameter in the .INI file, see

DirectSOFT FAQ0008.

DirectSOFT FAQ0074

06-Feb-2008

Q: Is it possible to turn OFF the automatic tracking of the Ladders

cursor by XRef in DirectSOFT5?

A: This tracking feature was added to DirectSOFT v5.0, but the

ability to turn this tracking OFF/ON wasn't added until DirectSOFT

v5.1. To turn this feature OFF (or back ON) in DirectSOFT v5.1 or

later, there are 2 ways:

DirectSOFT FAQ0075

25-Jun-2002

Q: Where can I get the DBWin32 program for helping troubleshoot

DirectSOFT links while the Dump feature is turned on?

A: This program is now installed with all versions of DirectSOFT

v4.0 or later. However, if you don't have it, it can be downloaded

here:

http://www.hosteng.com/SW-Products/SP_Demo_Utilites.htm#Utilities

DirectSOFT FAQ0076

18-Jul-2002

Q: Accessing the help in DirectSOFT and received the error:

"Cannot find the Progrun.hlp file. Do you want to try to find this

file yourself?"

A: This is a known bug in DirectSOFT v4.0 in Builds less than

(<) Build 20. As far as we know it only occurs in the following

manner:

To fix you can use the following work-around or simply download the latest Build.

DirectSOFT FAQ0077

24-Jul-2002

Q: At the PLC Password prompt, the mouse cursor remains an

hourglass and I am unable to click on the OK button.

A: This is a known bug in DirectSOFT. This was fixed in

DirectSOFT v3.0 Build 80 and v4.0 Build 18, so upgrading to at least

these builds is advised. A work-around is simply to press the

<ENTER> key on the keyboard.

DirectSOFT FAQ0078

06-Feb-2008

Q: Get "Unrecognized Tagname" error when Kepware imports Element

Documentation.

A: This can be caused by a bug in DirectSOFT v5.0 and v5.1. It was

fixed in DirectSOFT v5.2. Basically, if the XRef has never

been opened for your project, then the XRef database will never be

up-to-date with the program. Solutions:

DirectSOFT FAQ0079

06-Aug-2002

Q: When Merging two programs how are duplicate Nicknames and

Element Types handled?

A: When you invoke the Merge function, DirectSOFT asks you which

program should be given authority in such cases as duplicates.

DirectSOFT FAQ0080

06-Aug-2002

Q: Trying to open or import a project and get error "PLC type is

not supported by any installed knowledge base," or "Unknown file

format unable to import program," or "Can't load knowledge base."

A: You can get these errors for about four reasons. Below are the

ways and possible solutions:

DirectSOFT FAQ0081 (see

also DSData FAQ0016)

13-Feb-2008

Q: Upon starting DSData or DirectSOFT, get "Critical error 1004

invalid INI file."

A: The "INI file" is a reference pointing to the initialization

file for DSData and DirectSOFT (i.e. DS400.INI or DS500.INI files).

This error means one of two things (See 1. & 2. below):

- To make sure it can find the file use Start --> Run and type in "DS400.INI" (or "DS500.INI")

Press the <OK> button. This should pull up the .INI file in a default text editor (e.g. NotePad). If you get an error here then first try reboot the PC and try again. If it still doesn't work uninstall DSData (or DirectSOFT) and reinstall.

- Pull up the .INI file using Start --> Run and type in "DS400.INI" (or "DS500.INI")

Press the <OK> button. Look for "strange" or missing lines in the file. If there are any, it is best to delete the file entirely and then uninstall DSData (or DirectSOFT) and reinstall. You could try to edit it yourself and eliminate the problems in the file, but this would be at your own risk.

If none of the above works use the Search function on your PC and find all occurrences of the .INI file; delete them; uninstall DSData (or DirectSOFT) and reinstall.

NOTE: On a Win2K Server, the .INI file must be in the Administrator's WinNT folder.

DirectSOFT FAQ0082

28-Mar-2002

Q: Attempting Open/Close Project and get "DSP4x.exe" error and

"Unable to save workspace. Disk is write protected or file is

read-only!" error.

A: This is caused by the project files (mainly the .PRN and .WSP

files) being write-protected. If you copied the project from another

computer, a write-protected disk or possibly a CD-ROM this can occur.

To fix:

DirectSOFT FAQ0083

21-Oct-2002

Q: Using Win2K PC with DirectSOFT v4.0 Build 18. If I create a

Data View and save it to my server (e.g. mapped drive K:\), then

reopen it, make a change, and try to save it again, I get "Access to

K:\<pathname> was denied" error.

A: This is a know problem with MFC/Win2K. This means there is a

bug with MFC (Microsoft Foundation Classes) Win2K. MFC is a large

library of C++ classes developed by Microsoft. For Windows-based

applications written in C++, MFC provides an enormous head start. One

of the hardest parts of developing C++ programs (like DirectSOFT) is

designing a logical hierarchy of classes. With MFC, this work has

already been done. MFC is bundled with the C++ compiler that Host uses

to write DirectSOFT. Thus this "toolkit" though extremely useful, is

not perfect. In this case the problem is with this "toolkit" and not

with DirectSOFT.

To work around: Instead of using "Save" . . . use "Save As..."

DirectSOFT FAQ0084

01-Apr-2003

Q: Can the colors of the PID graph be changed?

A: No.

DirectSOFT FAQ0085

01-Apr-2003

Q: After upgrading from v3.0 to v4.0, is it OK to delete the v3.0

Projects folder?

A: Yes, but it is important to insure that you have copied your

old v3.0 projects (that you want to keep) to your v4.0 projects

folder. This can be done manually if need be. However, the upgrade

process will ask you if you want to do this, and it will do it for

you. It simply does a blind copy of the old v3.0 projects folder to

the v4.0 projects folder. Thus no files are lost (e.g. documentation).

All documentation is therefore kept with your project.

DirectSOFT FAQ0086 (see

also CTRIO FAQ0025; ERM FAQ0015)

02-Apr-2003

Q: In DirectSOFT (PLC --> Tools) there are listings for CTRIO

Workbench and ERM Workbench that I don't need. How do I get rid of

them?

A: We believe this could be caused by using Windows Uninstall

instead of the Workbenches' uninstalls; or perhaps storing these

software packages underneath non-default folders. Regardless, these

menu options are setup in the Windows Registry. To remove them

manually it is required that changes be made directly to the Registry.

This is not recommended for the normal user! And on some

PC's the Administrator does not permit it. However, if you dare:

Now in the right window you will see five string values:

To remove them completely right-click on a, b, InstallList and NextInstall one at a time and delete them. The only string value that should remain is (Default).

If you are plagued by multiple menu selections, then just make the registry entries look exactly like the above.

DirectSOFT FAQ0087 (see

also CTRIO FAQ0026; ERM FAQ0016)

02-Apr-2003

Q: Just selecting PLC --> Tools inside DirectSOFT causes my PC

to lock up.

A: We have found this to sometimes happen in versions earlier

than v4.0 Build 18, when you have installed CTRIO Workbench and/or ERM

Workbench under a different folder other than from c:\HAPTools. To

fix:

DirectSOFT FAQ0088 (see

also DS Data FAQ0042)

10-Apr-2003

Q: What is DBWin32 application?

A: It is a debugging tool used to troubleshoot and log vital

information for applications like DS Data and DirectSOFT Programming.

With DS Data it can be utilized in two ways:

With DirectSOFT Programming it can be utilized for troubleshooting only. Follow the same procedure as above except, of course, start DirectSOFT Programming instead of DS Data. When you start the applications (e.g. DS Data, DirectSOFT Programming) you may be asked if you are sure you want to dump information in the logger. Just answer "Yes."

DirectSOFT FAQ0089

15-Aug-2002

Q: My original DirectSOFT was PC-PGM-105. Will installing the v4.0

Upgrade gain me the ability to program the new DL06?

A: No. The PC-PGM-105 allows you to only program the DL05

and the DL105, and upgrading to v4.0 will not buy you the ability to

program a new DL06. To get DL06 programmability you must purchase at

least the PC-PGM-BRICK package.

DirectSOFT FAQ0090

15-Aug-2002

Q: Why does my DL06 link show up as a 250(-1) in DirectSOFT?

A: Earlier versions of the DL06 had DL250-1 firmware.

Upgrading the DL06 firmware will solve this. Firmware and firmware

upgrade tools can be downloaded from the Automation Direct website:

http://support.automationdirect.com/firmware/index.html. If that link

doesn't work:

Now you can download the Koyo support tool for upgrading the DL PLCs, as well as the specific DL06 firmware file.

DirectSOFT FAQ0091 (see

also DS Data FAQ0047)

16-Aug-2002

Q: I have DirectSOFT v4.0 Build 16, and in DS Launch, all the

versions show as v4.0.016 except for one; DSData.exe shows up as

v4.0.012.

A: This is a bug in v4.0 Build 16. To fix, upgrade to at

least v4.0 Build 18.

DirectSOFT FAQ0092

10-Aug-2018

Q: When I tried to delete an unused link in DS Launch I get a

CSMAIN.EXE error.

A: This is probably caused by a corrupt COMMSERV.RST file.

This is the file that stores all the links. Unfortunately there is no

way to repair this file. Therefore the only solution is the delete it

and re-create all your links again. It is stored in the DirectSOFT Bin

folder (see FAQ0025 above for location).

DirectSOFT FAQ0093

19-Aug-2002

Q: How can I tell if I have v3.0 Build 71 patch installed?

A: Follow these instructions:

The version of DEVASYNC.DLL should be v3.0.073.

DirectSOFT FAQ0094

19-Aug-2002

Q: Purchased PC-PGM-305 software. If I go to PLC -->

Diagnostics --> Scan Time, why is the Setup button grayed out?

A: This function is only supported in some CPUs (e.g.

DL405). None of the DL305s support this function.

DirectSOFT FAQ0095

18-Mar-2008

Q: Why does the FILTER (IB-422) and FILTERB (IB-402) Filtered Value

never seem to reach the Raw Data value?

A: This is due to the math of FILTER (BCD) and FILTERB (Binary)

being integer math (no fractions) and the fact that the filter

equation is:

New = Old + ((Raw - Old) / FD)

where:

New is New Filtered Value

Old is Old Filtered Value

Raw is Raw Data

FD is the Filter Divisor

Thus, if the Raw Data value remains unchanged for a long period of time, this inaccuracy in using integer math causes the Filtered Value to stop short of the Raw Data value by 1/2 of the Filter Divisor (due to our use of rounding) as can be seen in the above formula. For example, if you have a Raw Data value that swings between 0 and 4095, but you have a Filter Divisor of 20, and the Raw Data value remains unchanged for a long period of time at the value of 4095, then the Filtered Value will only reach a value of 4085. Likewise, at the low end, if Raw Data remained at zero (0), then Filtered Value would only reach 10.

This effect can be lessened by the use of Real (Floating Point) math. In other words, one could convert the Raw Data and Filtered Values from BCD (or Binary) to Real; do the math and then convert them back to BCD (or Binary). Of course to do this you could no longer use FILTER (IB-422) and FILTERB (IB-402) IBoxes. Mnemonically, the program for a filter using Real numbers might look like this:

STRN

T0

TMRF T0

K100

;

Fast Timer0 is used with a setting of 1 second

STR

T0

;

Calculation is done every second.

LDR

V2010

;

V2010 is the Raw Data to be filtered

SUBR

V2000

;

V2000 is the Filtered Value

DIVR

R20

;

In this example, FD is equal to 20.

ADDR V2000

OUTD V2000

We have plans of making another IBox that would filter using Real (perhaps called FILTERR) in a future release of DirectSOFT5.

DirectSOFT FAQ0096

07-Nov-2008

Q: Even after uninstalling DirectSOFT, I still have the

InstallShield Update Manager / Software Updates program on my PC.

How can I remove it?

A: DirectSOFT uses InstallShield to install itself on your PC. As

an added bonus, InstallShield installs an Update Manager / Software

Update program in order to keep you informed of updates made to

DirectSOFT. Since many other programs in the market use InstallShield

to install themselves on your PC, uninstalling DirectSOFT does not

uninstall this Update Manager / Software Update tool. If you are

confident that no other programs on your PC use this update tool, then

you can uninstall it by downloading the following .ZIP file, unzipping

it to its .EXE file and doubleclick on it to run it. Then just follow

the instructions. This uninstall program was taken from

InstallShield's website here:

http://consumerdocs.installshield.com/selfservice/viewContent.do?externalId=Q111006&sliceId=1

ZIP file: SoftwareManagerUninstall.ZIP

DirectSOFT FAQ0097

05-Sep-2002

Q: On WinME my DirectSOFT v4.0 Build 16 Backup failed and some of

the original documentation files are missing!

A: This is caused by having trailing spaces in your project

file name (e.g. ProjectName<space>.prj instead of

ProjectName.prj) and the fact that WinME was being used. WinME is

particularly affected by this because it cannot create directories

(which DirectSOFT v4.0 Backup attempts to do) with a trailing space in

the name. Other OSs (e.g. WinXP, Win2K) do not have this problem. But

if you have a ProjectName that has a trailing space in it and you

are using WinME, your original documentation files can be

corrupted or deleted if a Backup is attempted! This

problem is remedied in DirectSOFT v4.0 Build 18 or greater. We fixed

this by adding a trailing $ to any ProjectName with a trailing space.

To upgrade go here:

http://www.hosteng.com/SW-Products/DirectSOFT32/DirectSOFT32.htm#Service.

DirectSOFT FAQ0098

09-Dec-2008

Q: Working with DirectSOFT and get "DSP5x - The parameter is

incorrect"?

A: This error message is not from DirectSOFT but rather from the

install & update service that DirectSOFT used. This service used

to be called InstallShield, but then Macrovision and currently

Acresso. Searching their knowledgebase for this error, here are some

things that have helped others resolve this:

DirectSOFT FAQ0099

17-March-2010

Q: Is there a version of DirectSOFT that will run on a

Macintosh/Apple PC?

A: No, and Host Engineering has no plans of creating one in the

future. However, you might try a PC Emulator for the MAC PC. It is

possible that this could work, however, we can offer no support if it

doesn't.

DirectSOFT FAQ0100

21-May-2003

Q: Under View --> Options, Ladders tab, deselected 3D Tokens,

but if the project is closed, DirectSOFT doesn't remember the

setting.

A: To get DirectSOFT to remember the settings you must check the

"New Views" under the "Apply options to:" parameter:

DirectSOFT FAQ0101

27-May-2003

Q: Is DirectSOFT available in German?

A: No. Koyo makes DirectSOFT available in Japanese, but no other

foreign language is supported at this time.

DirectSOFT FAQ0102

09-Sep-2002

Q: What is the minimum requirement for PC to run DirectSOFT?

A: None. The general rule is that if it runs Windows, then

DirectSOFT should work on it. But performance is another issue. We

recommend:

Operating System: Win98, WinME, WinNT, Win2K or WinXP

CPU: Pentium III Class / 500MHz or greater

RAM: 64Mbytes

HardDisk: 20MBytes

PLC Connectivity: RS-232 serial port, USB port with

USB-to-Serial adapter, 10Base-T or 10-100 Ethernet NIC

This is the recommended system configuration for what we consider to be a good performing PC with DirectSOFT. As with any Windows application, a faster processor, more RAM, etc. will definitely improve the performance. While you can definitely run DirectSOFT on PCs with less capability, you run the risk of resource bottlenecks that can cause serious performance problems and in some cases, even system crashes. Fast CPUs and RAM are cheap, engineering time and system downtime aren't, plan accordingly!

DirectSOFT FAQ0103

11-Sep-2002

Q: Is it possible to convert a TI305 program to DL340 program?

A: Yes.

DirectSOFT FAQ0104

09-Dec-2008

Q: Can DirectSOFT be used across a network with projects stored on

a remote server (i.e. a network drive)?

A: DirectSOFT is not designed to work this way since it has to

have dynamic access to the files. If the files are not local, then

access to them could temporarily (or permanently) disappear and

DirectSOFT will not be able to access them on-the-fly. So, the best

way to do this is:

DirectSOFT FAQ0105

13-Sep-2002

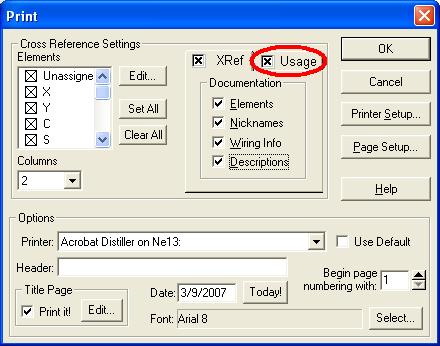

Q: Can you have the Usage view and Ladder view open simultaneously?

A: Yes, unless you have the Demo version. Otherwise Xref has two

views, Xref and Usage, and all can be open simultaneously.

DirectSOFT FAQ0106

19-Sep-2002

Q: Can the DL105 be put into RUN mode without DirectSOFT?

A: No.

DirectSOFT FAQ0107

20-Sep-2002

Q: Can the regular DirectSOFT package be installed over top of the

Demo version?

A: No. It is best to uninstall the Demo version before installing

the regular packages of DirectSOFT.

DirectSOFT FAQ0108

24-Sep-2002

Q: When using the Import function and selecting "delete existing,"

DirectSOFT still reported that there were conflicts between the

imported file and the existing documentation database.

A: This is a software bug and was corrected by v4.0 Build18.

DirectSOFT FAQ0109

04-May-2009

Q: Installing DirectSOFT and get "Error 13001: Product Not

Registered with FLEXnet Connect", or "Error 13003: Product Version

Not Registered with the Update Service."

A: This error comes from the fact that we have stopped using

FLEXnet as a license manager. Ignore this error because it will not

interfere with the operation of DirectSOFT, nor change its

functionality. It occurs in DirectSOFT v5.0 to v5.3 at the end of an

installation because that is when the Installer goes out and tries to

confirm the license via the FLEXnet server.

DirectSOFT FAQ0110

30-Sep-2002

Q: In DirectSOFT v3.0c the PID usable range was V36000-37777, but

in v4.0 the range is limited to V36000-36777.

A: True. The range stated in v3.0c is wrong. The correct range is

in v4.0.

DirectSOFT FAQ0111

14-Aug-2003

Q: How big can a single rung in DirectSOFT be?

A: A rung in DirectSOFT is a height/width matrix. The matrix

cannot exceed a size of 8192 cells. One cell in the matrix contains a

coil, contact or empty space. General guidelines:

Thus if you had 250 parallel output coils,

you could only have 32 series contact columns (250 x 32 = 8000).

Likewise, if you had 250 contacts in series (32 contact columns), then

you could only have 32 parallel output coils (250 x 32 = 8000).

These are good guidelines but not exactly correct. But being that the sizes are enormous we seriously doubt you will really need to know exactly how it is calculated. DirectSOFT will complain if there are any violations.

DirectSOFT FAQ0112

24-Sep-2003

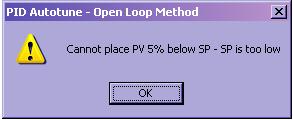

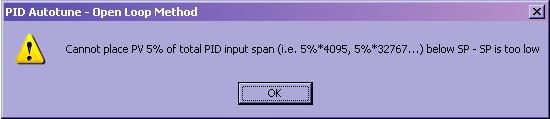

Q: When trying to Autotune a PID loop, the message "Cannot place PV

5% below SP - SP is too low" is unclear.

A: We changed the message to be much more descriptive in

DirectSOFT v4.0 Build 22:

Before v4.0 Build 22:

After v4.0 Build 22:

DirectSOFT FAQ0113

24-Sep-2003

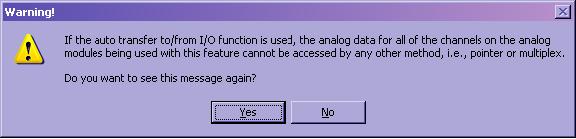

Q: I configured my PID loop to use the Auto Transfer for my analog

output card, but, my analog output card is not working properly.

A: Most of the time this is because having configured the Auto

Transfer for that analog output card, you are also trying to use the

pointer method of output to the same card. Therefore, we added the

following warning message in DirectSOFT v4.0 Build 22 to help

circumvent this from happening:

In later versions of DirectSOFT (i.e. > v4.0 Build 22) the above text will also include the following additional text, "In other words, if you select auto transfer to/from I/O, do not setup the analog in the ladder code. If you setup the analog in the ladder code, do not select auto transfer to/from I/O."

DirectSOFT FAQ0114

04-Nov-2002

Q: When trying to save a project I get "Filter error writing PLC

type."

A: This is more than likely a self-inflicted "wound" in that the

folder name for an open project must've been changed and then a Save

As... was attempted.

DirectSOFT FAQ0115

30-Sep-2003

Q: When trying to Configure I/O keep getting "Error reading from

disk."

A: This could be caused by:

However, the probable solution is just to Export the project and then Import it back. Or, sometimes deleting the TLS file, opening the project, and then resaving it works.

DirectSOFT FAQ0116

01-Nov-2003

Q: Can I make a DirectSOFT link over a VPN (Virtual Private

Network) to an ECOM?

A: This should work. However the NetEdit tool nor the

DirectSOFT Link Wizard will help because they utilize broadcasts; and

VPNs will block broadcasts. So the only link-aiding tool you will have

is the Ping command from a Command Prompt. If the VPN is set up such

that you can Ping the remote ECOM, this should work. You may have to

adjust the timeout values for the link, however.

DirectSOFT FAQ0117

03-Nov-2003

Q: PC crashed while transferring a project to the PLC. Now when I

open the project all I get is the comment for the first rung of

ladder logic but nothing else.

A: Whatever caused your PC to crash probably corrupted the

project file. If DirectSOFT isn't locked up then you can try a File

--> Export and then a File --> Import to see if this clears up

the project. Otherwise you will either have to start from a previous

backup copy (hopefully!) or start all over from scratch (yikes!).

Unfortunately this is the nature of a PC crash and there is no way to

UN-corrupt your project file.

DirectSOFT FAQ0118

09-Jul-2003

Q: Why does DirectSOFT beep at me after opening an offline project

for Koyo Kostac S-series, PZ1 and going into the Edit mode?

A: This was a bug in DirectSOFT related to the options on

the toolbar. To fix download the latest version of DirectSOFT, Build

22 or greater.

DirectSOFT FAQ0119

30-Sep-2009

Q: Using Cut (or Copy) and Paste with Ladder Comments and getting:

"Unable to write comments for rung xxx".

A: DirectSOFT's Cut and Copy do not place the data into the

Windows clipboard, but rather the data is written to temporary files

(CLIPPGM.LBD & CLIPPGM.LBX) that is pointed to by the PROJECT PATH

parameter in the .INI file (DS400.INI for v4.0; DS500.INI for v5.x).

Thus, problems are centered around this fact. Generally this error is

caused by one of the following:

DirectSOFT FAQ0120

21-Nov-2003

Q: Every time I open a project, it tries to connect online to my

PLC, which may or may not be connected. How can I prevent this from

happening?

A: This happens because the project was saved while

connected to the PLC (i.e. it is an ONLINE PROJECT). If you don't want

this to happen, then before you save the project, use PLC -->

Disconnect.

DirectSOFT FAQ0121

21-Nov-2003

Q: Every time I open DirectSOFT it wants to create a new project by

default and I have to close it. Is there a way for it to open up and

not do this?

A: This happens because you did not open DirectSOFT with an

existing project, so it "thinks" you must want to create a new one. If

all you want to do is open up existing projects then the easiest thing

to do is use DS Launch (Start --> Programs --> DirectSOFT32

--> DS Launch). From here DS Launch remembers the projects you had

opened previously and all you have to do is double-click on the

correct project under the Projects icon and DirectSOFT will open up

with this project instead of trying to create a new one.

DirectSOFT FAQ0122

21-Nov-2003

Q: In Ladder View the Syntax Check button is grayed out and I can't

use it. Why?

A: This is because the link you are using is configured for

DirectNet protocol, and DirectNet protocol does not allow this.

With DirectNet protocol:

With K-sequence protocol:

If you will edit the link and change the protocol to K-sequence then the Syntax Check button will work (PLC --> Link Setup... --> Edit... --> Protocol). Or better yet, if you are using an ECOM then pick the ECOM protocol because the ECOM will then use DirectNet when it can and K-sequence when it needs to:

DirectSOFT FAQ0123

21-Nov-2003

Q: When viewing status in Ladders and attempting to use the Change

Value button to change a bit (X, Y, C, etc.), the Write-to-PLC

button is grayed out. Why?

A: This is because the link you are using is configured for

DirectNet protocol, and DirectNet protocol will not allow bit writes.

With DirectNet protocol:

With K-sequence protocol:

If you will edit the link and change the protocol to K-sequence then the Write-to-PLC button on the Change Value dialog will work (PLC --> Link Setup... --> Edit... --> Protocol). Or better yet, if you are using an ECOM then pick the ECOM protocol because the ECOM will then use DirectNet when it can and K-sequence when it needs to:

DirectSOFT FAQ0124

08-Dec-2003

Q: Can V-memory bits have their own Nicknames, Wiring Information

and Descriptions?

A: Yes. A V-memory address (e.g. V2000) can have its own

documentation as a word; but each of its 16 bits (designated by by

B2000.x; where x is the bit number) can also have their own

documentation. Park the cursor on the B bit in ladders view and then

go to Tools --> Documentation Editor... to edit them.

DirectSOFT FAQ0125 (see

also DS Data FAQ0069)

26-Sep-2002

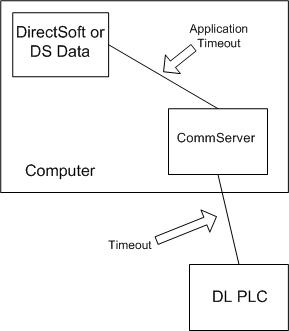

Q: When configuring a link, on the Port tab, Advanced Settings,

what does "Application Timeout" VS "Timeout" mean?

A: Refer to the diagram. "Application Timeout" is the time

the client will wait on the link CommServer for a response. "Timeout"

is the time the CommServer will wait for a response from the PLC.

DirectSOFT FAQ0126

09-Dec-2003

Q: When trying to open a project, I get "Error 1006: Module load

failure = 126 in module c:\DirectSOFT32\Knowbase\KB430M.DLL."

A: The number "126" in this message is a Global Windows

System Error number. Therefore this error is some kind of Windows

system problem. In general "Error 1006" is telling you it couldn't

open the file named and the reason is the Windows System Error, so the

first thing to do is to make sure that the file being named is

actually there. We have also seen other variants of this error that

report different a Windows System Error number and different files.

Here are some we've seen:

The number "31" is designated by Microsoft

as ERROR_GEN_FAILURE.

The number "126" is designated by Microsoft as ERROR_MOD_NOT_FOUND.

The first thing to check is to see if there are any files in your DirectSOFT Projects folder that have the extension of DLL. If there is, delete them.

Secondly, we have found that doing the following steps has made any and all of the rest of the variants of this error disappear even though we admit we don't know specifically why.

DirectSOFT FAQ0127 (see

also DNLoader FAQ0001)

09-Jan-2004

Q: Is there a software utility that can be used to upload/download

programs without using DirectSOFT?

A: Yes. Host Engineering has created a free program called

DNLoader that does just that. You would use it to read the program and

(optionally) the retentive V-memory from a DL PLC and save this data

in a file. This file cannot be read by DirectSOFT. You can then use

DNLoader to write the contents of this file to another DL PLC of the

same type. It supports serial or Ethernet connections and also

supports PLC Passwords. It is the ideal tool for an OEM or System

Integrator. You can download your copy from our website under the

Support --> Utilities section.

DirectSOFT FAQ0128

22-Sep-2009

Q: When a Data View is Exported to a .CSV or .TXT file, it is

always empty (blank)!

A: This is a bug in DirectSOFT v5.3 and earlier, but

fortunately there is a work-around. This only happens if the Data View

you are trying to Export is not docked (i.e. it is floating) to the

main DirectSOFT application frame. Thus, grab the Data View and drag

over to the main DirectSOFT application frame until the docking

graphic appears and release it there. Then the Data View Export should

work just fine. See example pics below:

Notice the Data Views (Data1, Data2),

though grouped together, are still undocked from the main DirectSOFT

application frame:

Notice now the Data Views (Data1,

Data2), still grouped together, are now docked to the main DirectSOFT

application frame:

This bug will be fixed in the next release of DirectSOFT5.

DirectSOFT FAQ0129 (see

also DS Data FAQ0070; ECOM FAQ0030; NetEdit FAQ0009)

03-Nov-2002

Q: Does the ECOM work with DHCP? Or does the PC's NIC have to have

a static IP address in order to communicate with an ECOM?

A: The ECOM does not support DHCP addressing, (ECOM100s support

DHCP). The ECOM must have a static IP address. However, the PC that is

talking to the ECOM does not have to have a static IP address. Things

to consider:

DirectSOFT FAQ0130

13-Aug-2002

Q: Can I install DirectSOFT on a LAN Server and then have multiple